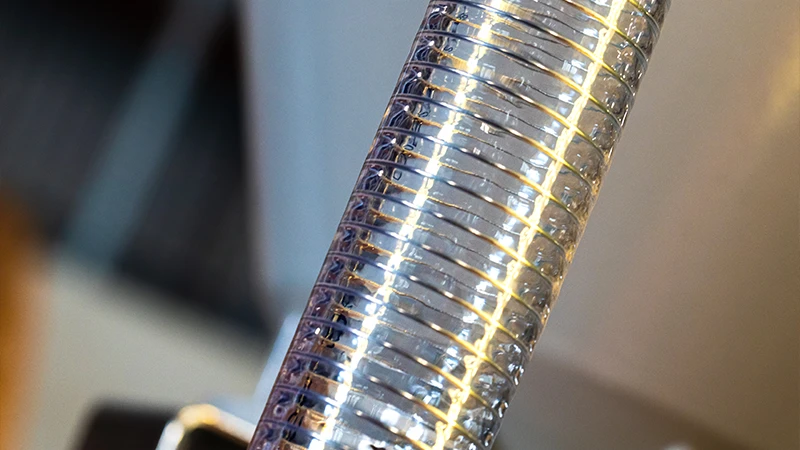

PRODUCTION

Reliable Quality and Innovation

with Industrial Solutions

With high-performance chemicals, esters, industrial raw materials and special formulations, we optimize your production processes and increase your efficiency. Become a reliable business partner in industrial production with our environmentally friendly and innovative products!

Industrial Chemicals

OLEXSOL ESB Epoxidized Soybean Oil is used as a stabilizer and plasticizer in PVC and other plastic applications. It provides high heat and light resistance. OLEXSOL SS-75 Sodium Dioctyl Sulfo Succinate is preferred as a wetting agent in textile and agricultural applications.

Monohydroxy Alcohol Esters

Our products such as OLEXSOL OL-P 2-Ethyl Hexyl Oleate and OLEXSOL OL-E Epoxy Alkyl Oleate are used as lubricants and mold release agents in PVC processes, as well as in the production of mineral oil and artificial leather. It stands out with its high thermal stability and environmentally friendly features.

Methyl Esters

OLEXSOL ME (101,102) Fatty Acid Methyl Esters are used as lubricants in textile, ink and paint production with their low viscosity and high flash point properties. They are also preferred as oil carrier base material in cosmetic and agricultural applications.

Industrial Raw Materials

Oleic Acid, the basic raw material used in production processes, is available in our stocks and is widely used in the industrial chemical sector. You can contact us for detailed information.

SPEACILITY PRODUCTION

For Industrial Inquiries,

Your Reliable Solution Partner

Dedicate Analysis and Product Development

A detailed analysis is done to understand the customer's needs and requirements. Design of the product is planned in accordance with customer demands and specifications and the design process is started.

Pilot production and Testing

Once the design is completed, a pilot type quantity is produced. This quantity is tested for functionality, quality and meeting customer’requirements. Necessary improvements and arrangements are made.

Production Planning & Mass Production

Once the prototype is approved, a production plan is created. At this stage, the production line is prepared, necessary materials are procured, and mass production begins.

Quality Control and Delivery

Every product produced is subjected to quality control processes and its compliance with the determined standards and customer requirements is checked. After quality approval, the products are shipped for delivery to the customer.